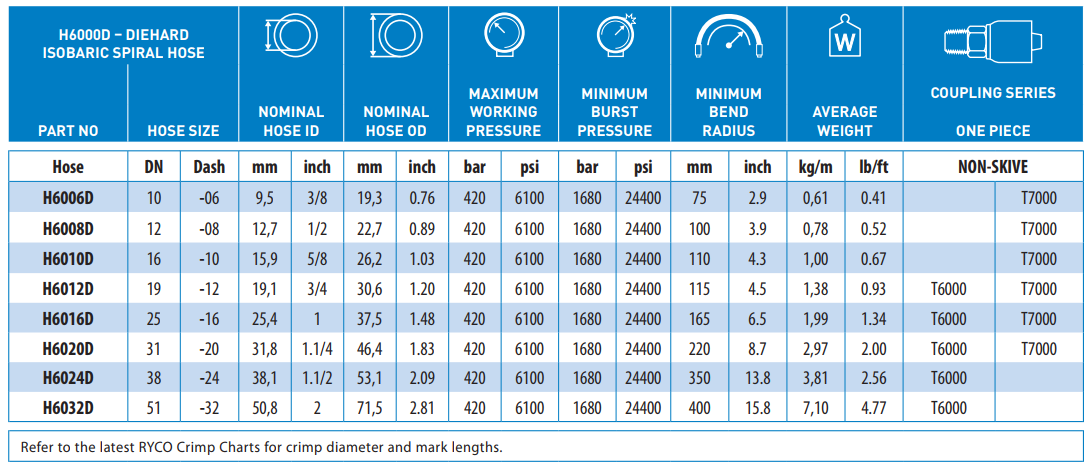

RYCO H6000 – ISOBARIC SPIRAL

EN 856 Type R15, ISO 18752-CC, SAE 100R15.

RECOMMENDED FOR:

Extremely high pressure hydraulic oil lines. Constant

pressure (Isobaric) 420 bar / 6100 psi in all sizes. Small bend

radius is an advantage in installations.

PERFORMANCE:

Meets or Exceeds the Performance Requirements of:

EN 856 Type R15, ISO 18752-CC, SAE 100R15.

TUBE:

Black, oil resistant synthetic rubber.

REINFORCEMENT:

Four (-06 to -16 size), six (-20 to -24 size) and eight (-32 size)

alternating layers of spiralled high tensile steel wire.

COVER:

DIEHARD™ Black, oil and extra abrasion resistant synthetic

rubber. Flame Resistant, Anti-Static (FRAS) & MSHA

compliant. Highly visible layline branding for easy and

permanent identification. No skiving required with T6000

and T7000 Series Crimp Couplings.

FEATURES:

Tested to 1 million impulse cycles at up to 1/2 SAE 100R15

Minimum Bend Radius. World First: World’s first 2” (-32) hose

tested to 1 million impulse cycles at 400mm (15.8”) Minimum

Bend Radius. Constant pressure 420 bar / 6100 psi in all sizes

for easy system design and hose selection. Small bend

radius is an advantage in installations.

FRAS – FLAME RESISTANCE AND ANTI-STATIC:

DIEHARD™ complies with Flame Resistant and Electrical

Resistance (Anti-Static) requirements of Australian Standard

AS 2660 and Methods of Test AS 1180.10B and 13A.

Meets Flame Resistant Designation “U.S. MSHA” of the US

Department of Labor, Mine Safety and Health Administration.

TEMPERATURE RANGE:

-40°C to +121°C (-40°F to +250°F).

For water, emulsions etc. see page 58.

WORKING PRESSURE:

Maximum working pressures are based on 4:1 safety factor

(maximum working pressure to minimum burst pressure).

THIRD PARTY APPROVALS:

ABS, DNV-GL, LR, MED, USCG, GOST-R, BV, RINA and KR.

COUPLINGS:

NON-SKIVE ONE-PIECE CRIMP

T7000 Series (sizes -06 to -20) pages 272 to 302.

T6000 Series (size -12 to -32) pages 250 to 270.

Assembly Instructions pages 478.

Đánh giá ỐNG THỦY LỰC ĐẲNG ÁP 4-6-8 LỚP KẼM (WP 6100PSI/420BAR)

Chưa có đánh giá nào.